The SOUDURE blog aims to introduce you to various welding machines and welding equipment.

Whether you are a beginner or an experienced professional, you will find practical advice here to improve your welding skills. Mastering welding techniques, spot welding, and the use of a dent puller (stud welder / pull pin system) is essential in automotive body repair. Discover our comprehensive guide to modern welding processes and professional welding machines.

TIG, MIG MAG, MMA, SPOT WELDING AND STUD WELDING FOR DENT REPAIR

Trusted and verified affiliates links

Welding Machines and Welding Processes

Professional welders must be able to work with various welding processes. The most common include MIG/MAG welding, TIG welding, and manual metal arc welding (MMA). Each of these processes uses a welding torch or electrode holder along with filler material—typically welding wire or electrodes—to produce strong, durable welds.

TIG Welding

TIG welding (Tungsten Inert Gas welding) uses a non-consumable tungsten electrode combined with an inert shielding gas. Argon protects the weld pool from oxidation and contamination.

MIG/MAG Welding

Semi-automatic processes such as MIG/MAG welding use a wire feed system that continuously supplies the welding wire. This makes it particularly suitable for large surfaces and the assembly of heavy or large metal components.

MMA Welding (Stick Welding)

MMA welding stands for Manual Metal Arc welding, also known as stick welding. It is one of the most widely used welding processes, valued for its simplicity, reliability, and versatility. The coated electrode creates and maintains the arc while producing shielding gases and slag that protect the weld from oxidation and atmospheric contamination.

Spot Welding

Spot welding is a widely used welding technique across many industrial sectors, particularly in automotive manufacturing and sheet metal fabrication. This process uses electrical resistance to fuse metal parts together. Copper electrodes apply precise heat and pressure to create consistent, high-quality weld spots.

Stud Welding for Dent Repair

This automotive body repair process is an efficient and proven technique for restoring damaged vehicle structures. It combines stud welding with spot welding technology to attach pull pins to the vehicle body, allowing dents and deformations to be pulled out accurately—an essential method for professional body shops.

Welder training includes learning different welding techniques, the correct use of welding machines, and compliance with essential safety and quality standards. Professional welders must also be able to detect and correct welding defects such as cracks, porosity, or inclusions to ensure strong and long-lasting welded joints.

TIG Welding

TIG welding (Tungsten Inert Gas welding) is a highly precise arc welding process known for its exceptional weld quality and clean finish. It is widely used in automotive bodywork, industrial fabrication, precision metalwork, and the manufacturing of aluminum and stainless steel components. The process relies on a stable arc, a tungsten electrode, and inert gas shielding.

TIG welding offers excellent control over the weld pool and produces virtually spatter-free welds with a high-quality appearance. It is ideal for demanding applications requiring precision, strength, and clean results, especially when working with stainless steel, aluminum, and thin materials.

MIG/MAG Welding

MIG/MAG welding (Metal Inert Gas / Metal Active Gas) is one of the most productive welding processes used in industry, automotive repair, and metal fabrication. The continuous wire feed allows for high welding speeds and consistent weld quality.

MIG welding with inert gas is ideal for aluminum and stainless steel, while MAG welding with active shielding gas is best suited for mild steel and carbon steel. Thanks to its versatility, ease of use, and reliability, MIG/MAG welding is a preferred solution for automotive repairs, steel structures, and industrial welding applications.

MMA Welding

MMA welding (Manual Metal Arc welding) is a robust and widely used process that does not require shielding gas. It is particularly suitable for outdoor work, construction sites, and welding thick or oxidized metals where mobility and reliability are essential.

Using coated electrodes, MMA welding allows for reliable welding of steel, cast iron, and structural metal components. Although it requires more skill to master slag removal and weld pool control, it remains an essential solution for repair work, construction projects, and heavy-duty welding tasks.

Spot welding

Spot welding is a method of resistance welding. It is primarily used in the automotive industry to assemble metal parts quickly and durably. This technique involves applying strong pressure and a high-intensity electric current to two or more overlapping metal sheets.

The electrical resistance at the metal interface generates enough heat to locally melt them. This forms a solid weld once cooled.

The main use of spot welding in the automotive industry lies in assembling body panels and the metal structures of vehicles. This method is appreciated for its speed and efficiency. It allows the production of thousands of weld spots in a single production day. It also offers high precision, essential for maintaining the strict tolerances required in automotive manufacturing.

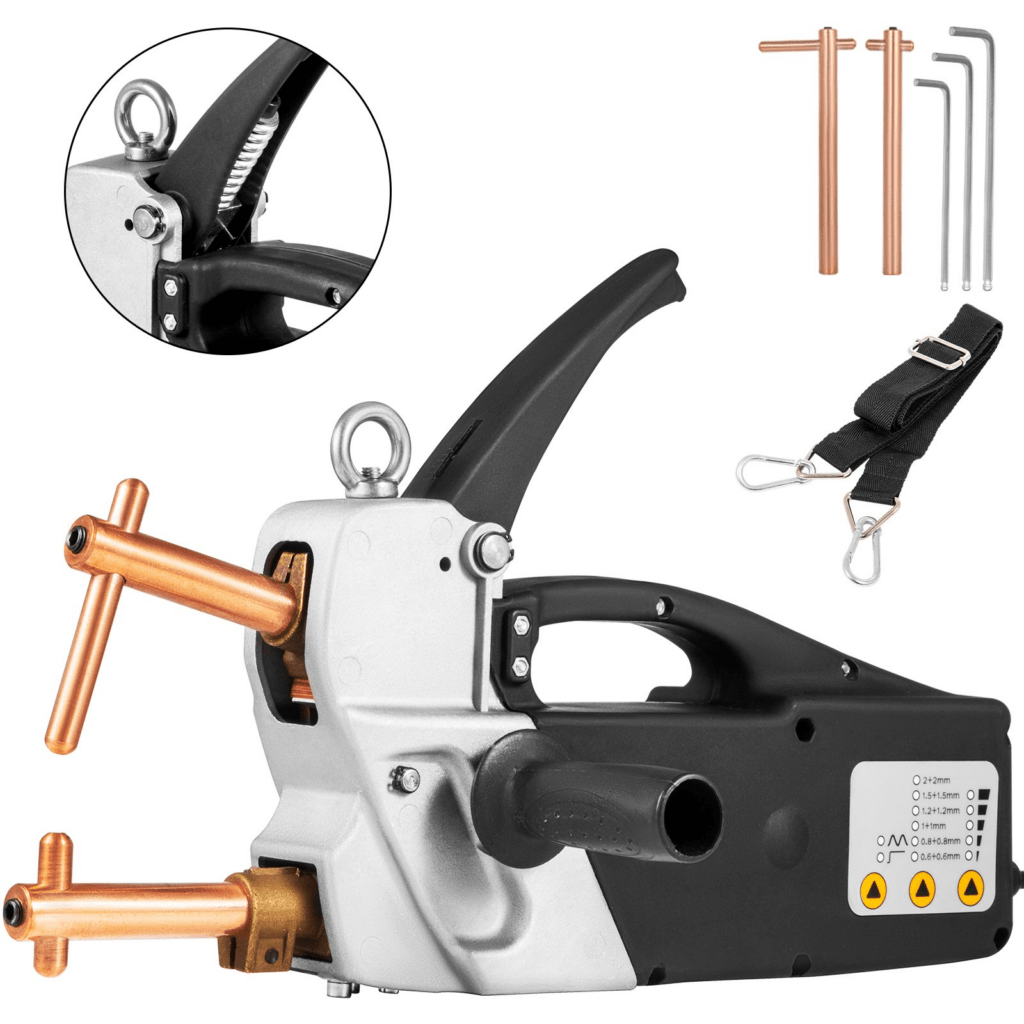

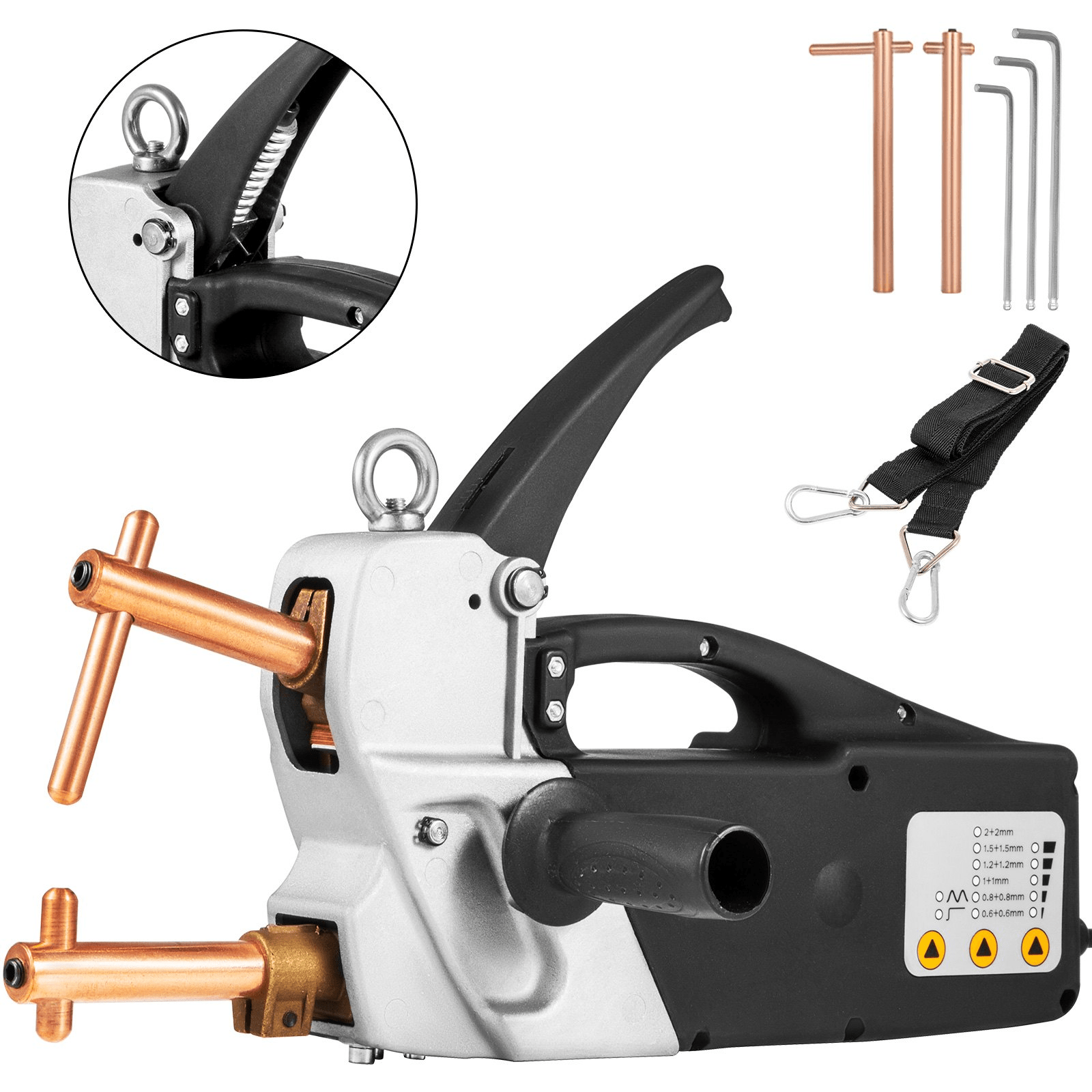

Stud welder

A nail puller is primarily used in bodywork workshops. It serves to straighten dents and deformations in sheet metal panels. It works by welding nails or special pins onto the damaged surface of the sheet metal. Once welded, these nails serve as anchor points to apply tension and straighten the sheet metal.

The damaged area of the sheet metal must be cleaned to ensure good adhesion of the nails. A nail puller quickly welds nails at specific points on the sheet metal. The welding occurs through a short electric current pass through the nail, generating enough heat to fuse the nail metal with the sheet metal.

A traction tool (usually an inertia hammer or a lifting device) is attached to the welded nails. By pulling on this tool, the technician applies controlled force to straighten the sheet metal.

Once the sheet metal is straightened, the nails are removed, and the surface can be sanded and finished to eliminate any remaining imperfections.

This process allows for the repair of body panels without having to disassemble the parts. This provides a quick, precise, and cost-effective solution for all interventions and repairs.

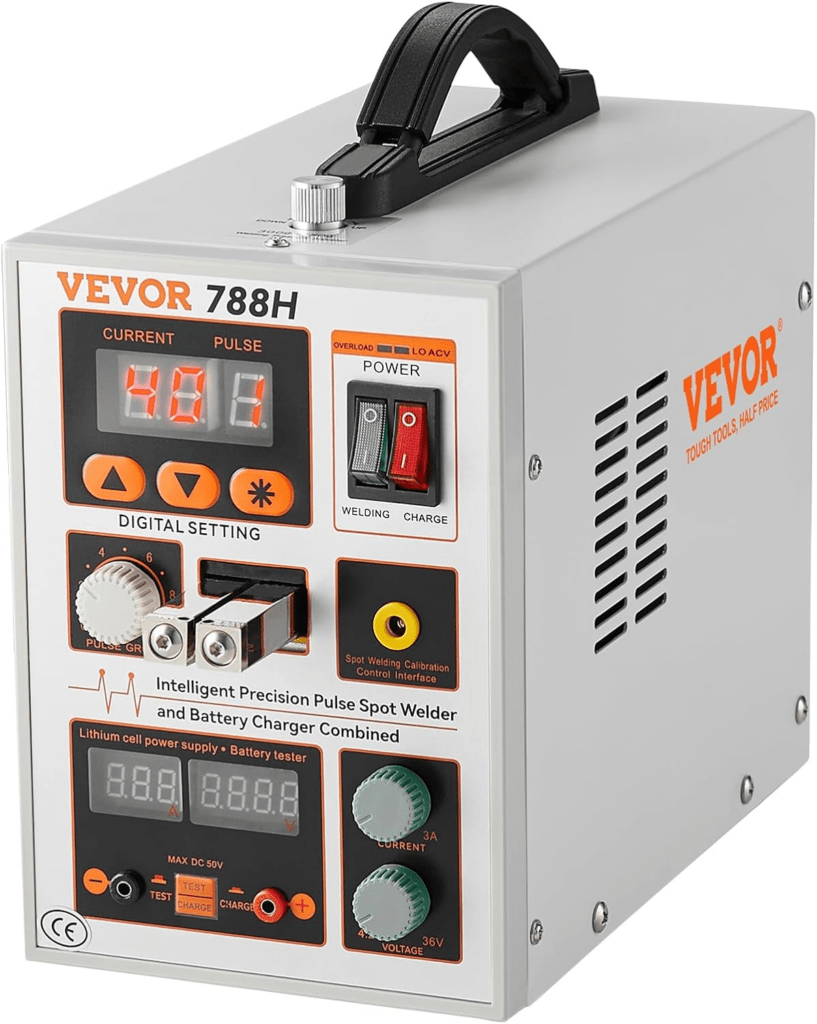

Battery welder

A battery welder or spot welder for batteries allows the manufacture of batteries based on lithium-ion cells. It works by spot welding the batteries to special conductive strips. Once welded, these strips serve as points in the battery’s series or parallel electrical network.

Battery spot welding is currently of particular interest. With the advent of electric vehicles, more and more people are looking to utilize these propulsion methods. For example, electric bicycles are significant battery consumers. When you consider the price of a bicycle battery, the interest in building your own battery becomes clear. This involves assembling cell packs in a safe and efficient manner. For this, you need a specialized spot welding method. You must be able to connect nickel tabs to each terminal of the battery cells.

Everyone can thus create their own battery by varying the number of cells and adapting their desired geometric configuration. The battery can be easily installed in the chosen location. Building a bicycle battery is just one example among many. Why not create your own scooter, electric skateboard, or other means of transport requiring an electric battery?

VEVOR

The VEVOR brand has established itself as a key reference in the field of professional electric welding, thanks to equipment that combines performance, reliability, and accessibility. VEVOR welding machines are designed to meet the needs of craftsmen, industrial operators, and metalworking professionals seeking efficient solutions for their welding tasks.

Whether MMA, TIG, or MIG welding units, VEVOR offers a wide range of robust machines equipped with modern technologies that ensure precise, stable, and safe welding. Known for its excellent value for money, VEVOR welding equipment is suitable for both intensive work and maintenance or fabrication applications.

With ergonomic design, controlled power, and great ease of use, VEVOR welding machines adapt perfectly to demanding professional environments while ensuring durability and consistent performance.

rer Modification de code Sortir de l’éditeur de code Lien sites Écrivez du texte ou du HTML