The blog WELDER has to introduce you to different spot welder used in automotive or construction of batteries. This relates to the welding point during the repair of sheet metal automotive or manufacturing of electric batteries with a battery welder.

Different techniques and tools welding to get professional results will be presented.

Whether you’re a beginner or an expert, you will find here practical tips for perfecting your art of welding points. You maximizing your bodywork repairs and your creations batteries.

The spot welding is a welding technology that is very widespread in various industrial sectors. This is especially true in the metal and the sheet metal. This process mainly uses an electric arc to fuse metal parts. The electrodes are usually made of copper. They transmit the heat and pressure necessary to achieve the welding point. The welding machine is often an inverter. It is portable and capable of providing a continuous flow stable. It is essential for this type of welding.

The various welding processes

Welders are required to master various soldering processes. The MIG / MAG, TIG, and the welding, the arc covered electrodes are the main processes. Each of these processes use a welding torch and the filler metal. It is often in the form of a rod or wire filled to create welds solid. TIG welding uses a tungsten electrode and an inert gas. The argon gas protects the weld from contamination.

The choice of shielding gas, such as argon or helium, is crucial to prevent the oxidation. This ensures proper penetration of the weld. Welders also need to choose the right type of welding. It depends on the materials to be welded. This is the stainless steel, cast iron, alloys or thin sheet metal.

The process is semi-automatic, as the MIG / MAG, uses a reel to continuously feed the welding wire. It also facilitates the welding work on large surfaces or parts to assemble large. Arc welding is the practice in manual mode. It can be done with a generator automated for welding operations are repetitive and precise.

The setting

When welding, the polarity, the current (ac or dc) and amperage must be carefully addressed. They depend on the material and the thickness of the parts to be welded. The use of a mask welding and a hood for protection is indispensable. This protects the eyes and skin from splashes and UV rays produced by the electric arc.

The specific case of the welding point

Spot welding is especially effective to assemble thin sheet metal, in the car, for example, where speed and precision are crucial. Each welding point sapplied in a weld time is very short. It allows you to weld the pieces quickly and efficiently without too much heat to the surrounding materials. This reduces the risk of deformation.

The welding training includes learning the different welding techniques, the use of the different types of welding station, and the important safety rules. Welders, professionals must also know how to detect and correct the faults of welding, such as cracks or inclusions, to ensure assemblies, solid and durable.

Spot welding and other welding processes require a thorough knowledge of equipment, materials, and welding techniques to achieve quality welds. Tools such as the torches, electrodes, generators, and protective gas all play a crucial role in the success of the welding operations, whether for maintenance, manufacturing, industrial, orcrafts.

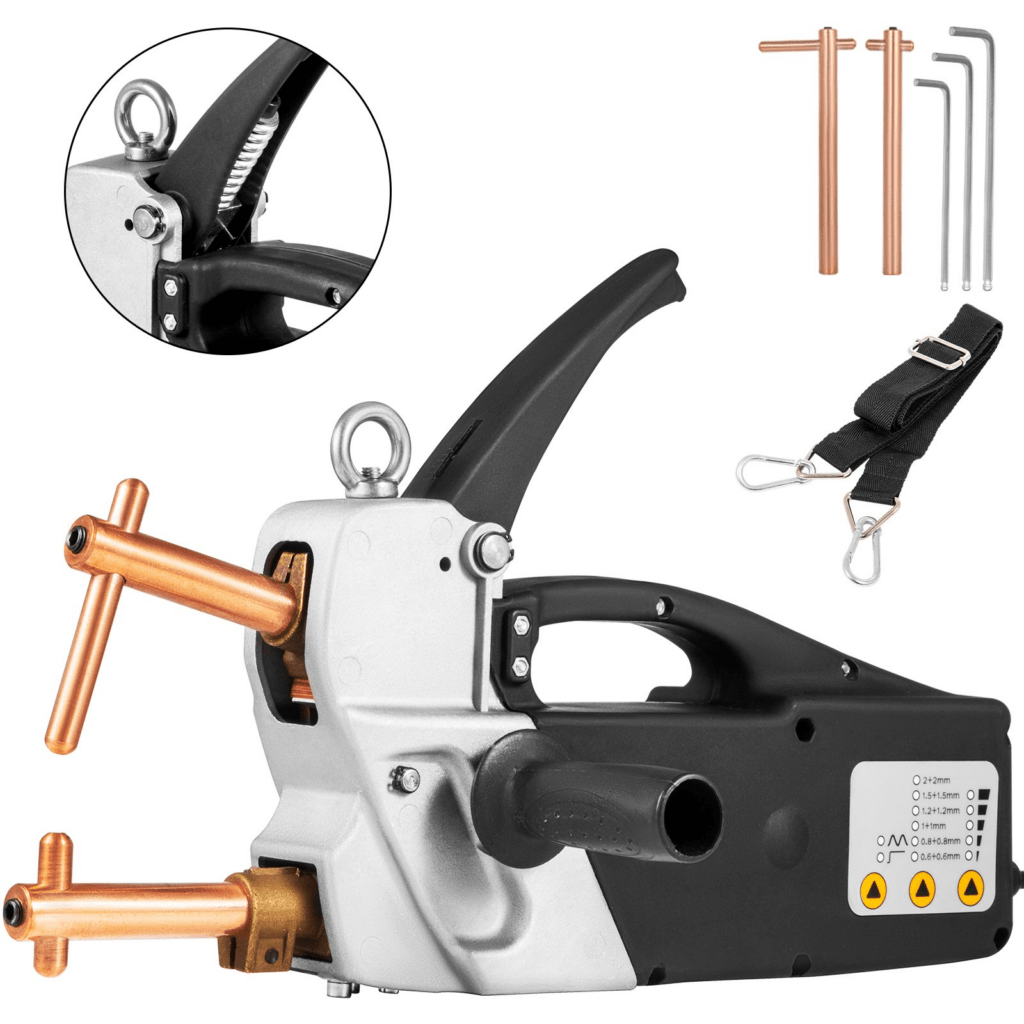

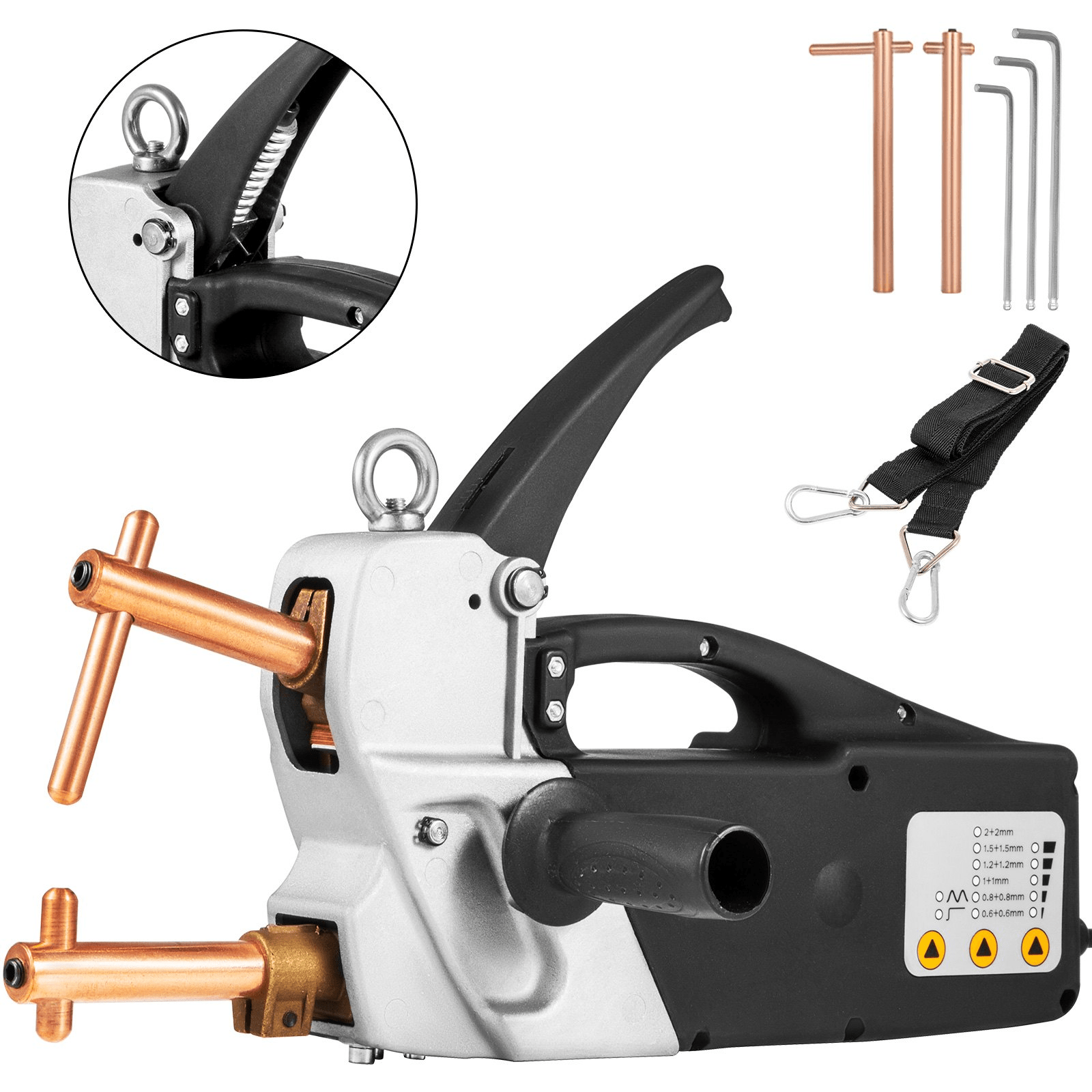

Spot welder

The ‘spot welding’, or ‘spot welding’ is a method of electric resistance welded. It primarily serves the automotive industry to assemble metal parts, rapid, and sustainable. This technique consists of applying a high pressure, and an electrical current of high intensity two or more sheets of metal stacked.

The electrical resistance at the interface of metals generates enough heat to melt locally. It thus forms a weld solid once cooled.

The main use of the spot welding in theautomotive industry lies in the assembly of the body panels and metal structures of vehicles. This method is appreciated for its speed and efficiency. It allows thousands of welding points in a single day of production. It also offers a great precision, which is essential to maintain the tight tolerances required in the automotive manufacturing.

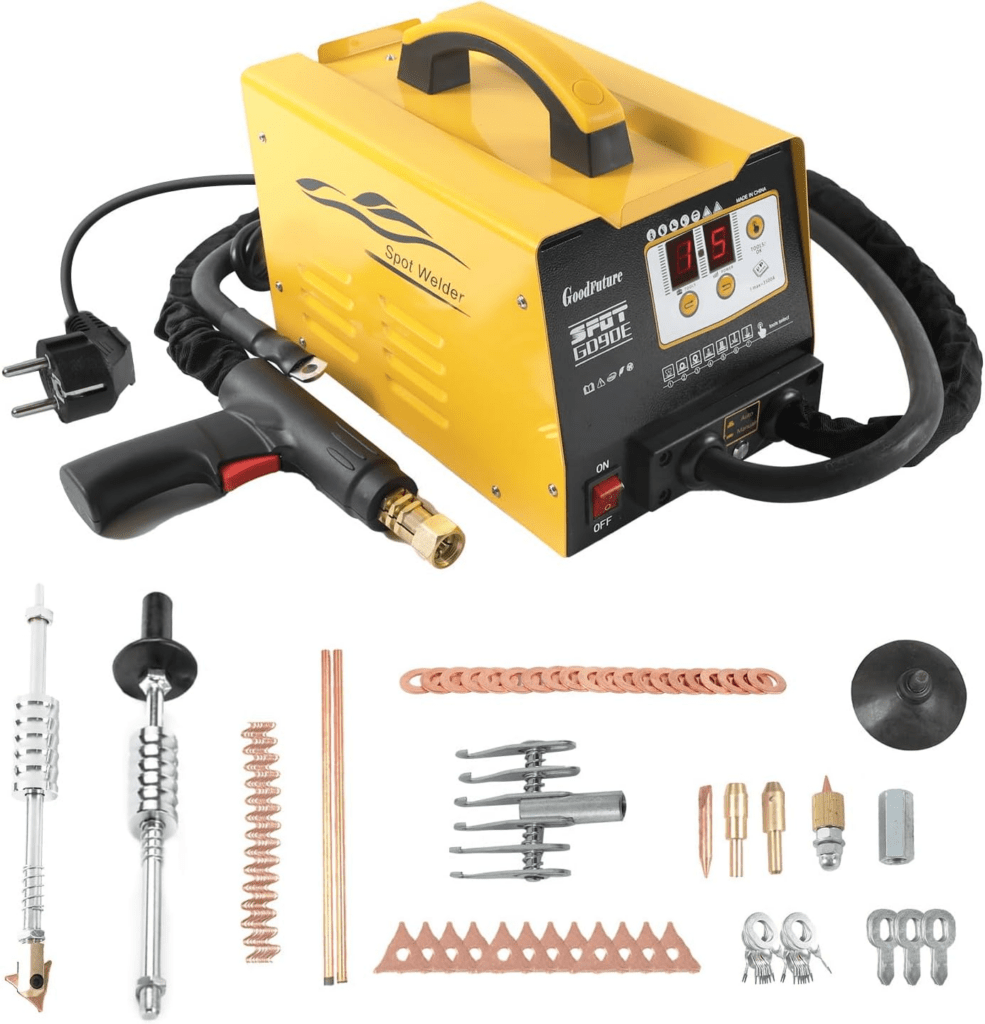

Stud welder

A ‘stud welder’, or ‘pulls nails’, smainly used in auto body shops. It is used to straighten the dents and deformations of the sheet metal panels. It works by welding of nails or pins special on the damaged surface of the sheet. Once welded, these nails are used as points ofanchorage to apply traction, and straighten sheet metal.

The damaged area of the sheet metal should be cleaned to ensure a good grip of the nails. A stud welder soda rapidly nails at specific points of the sheet. The welding is carried out by a short passage of electric current through the nail, generating heat sufficient to fuse the metal of the nail with the plate.

A tool of power (usually a hammer to inertia or a lifting device) is attached to the studs welded. By pulling on this tool, the technician performs a controlled force to straighten the sheet.

Once the plate adjusted, the nails are removed, and the surface can be sanded and finished to remove any imperfections remaining.

This process allows you to repair the body panels without having to disassemble the parts. This is providing a solution that is fast, accurate and cost-effective for all intervention and repairs.

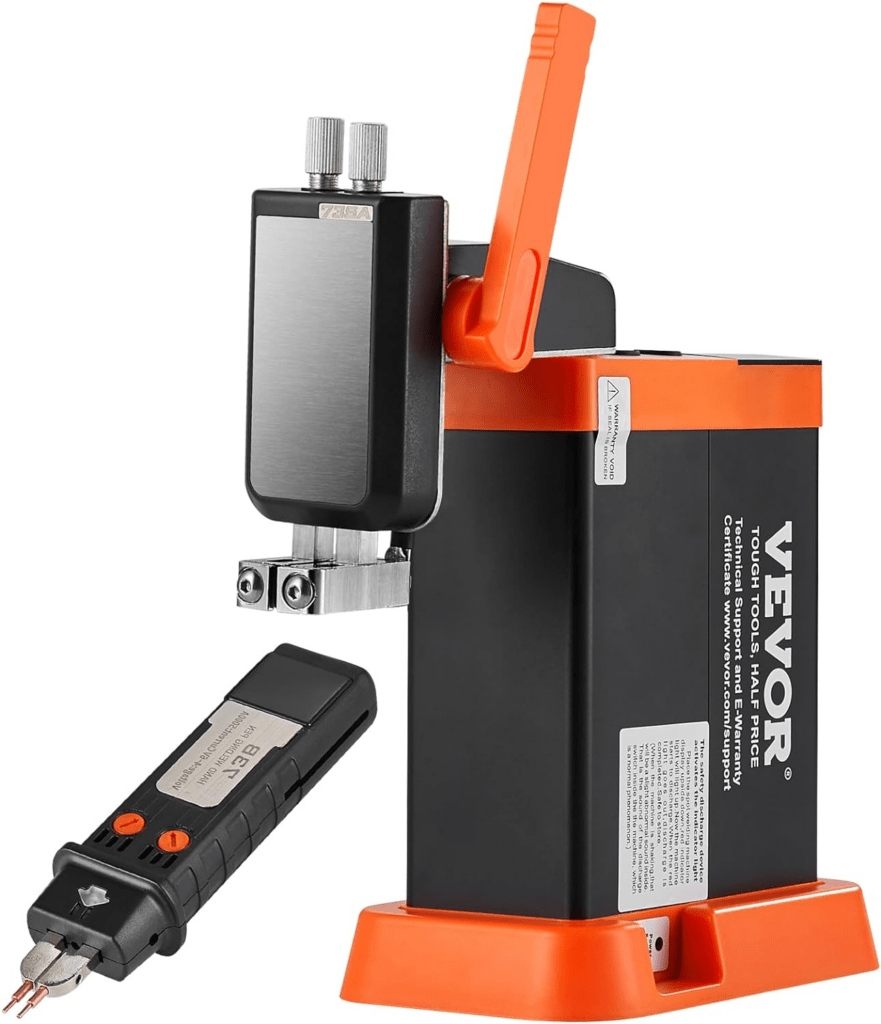

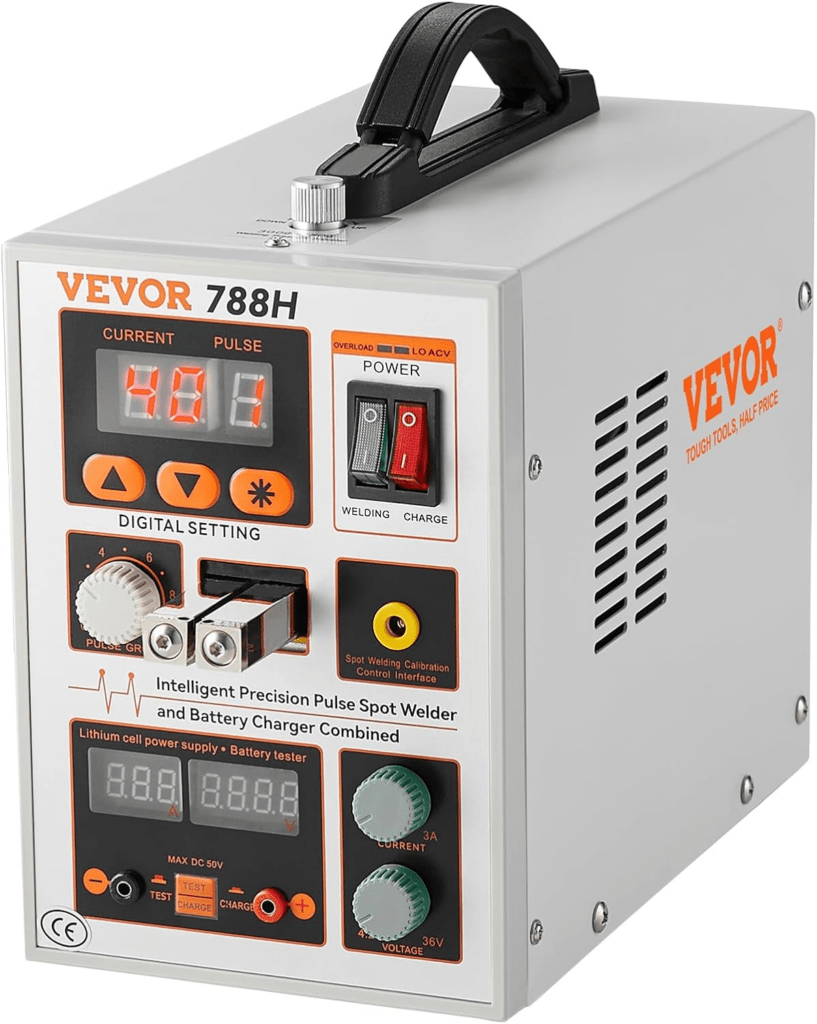

Battery welder

A ‘Battery spot welder’, or ‘welder-by-point for battery’ is a tool primarily used in the manufacture of batteries. It works by soldering the batteries of the slats conductive special. Once welded, these slats are used as the points in the electrical network, serial, or parallel to the battery.

Intérêt

The spot welding for batteries takes a particular interest at this time. With the advent of the electric, more and more people seek to exploit these means of motorization. The electric bicycle, for example, is a very large consumer of battery power. When we observe the price of a bike battery, we understand the interest to build up its own battery. It is then assemble packs with cells more effectively and securely. For this it is necessary to have a means of spot welding specialist. You need to be able to connect the tabs in nickel to each terminal of the battery cells.

Everyone can create its own battery while playing on the number of cells and by adjusting its geometric configuration desired. The battery can easily be installed in the selected location. The creation of a bike battery is one example among plenty of others. Why not create its own battery scooter, board electric or other means of transportation requiring an electric battery.

Technique

The spot welding for batteries is an essential technique to assemble packs with cells more effectively and securely. This method uses a position of spot welding specialist to connect strips of nickel to the terminals of the battery cells. The tabs are cut to the appropriate length. They are cleaned to ensure good conductivity.

The cells in a battery holder, aligned according to the desired configuration, where it be in series or in parallel. The post welding is set with precision, adjusting the power and duration of the pulse welding to avoid damage to the cells while ensuring welds are strong. Each tab holds with a pulse-controlled connecting firmly cells. The final connections must be insulated to prevent short circuits.

Assemblage

After the assembly, the battery testing with a multimeter to check the voltage and ensure a balanced operation. Tests of charge and discharge are also performed to validate the performance. This process allows for batteries to be reliable and durable, which is essential for various applications, ranging from electronic devices to laptops to electric vehicles, while ensuring security and efficiency.