The spot welder or spot welding in French, in addition to being quick and efficient, which allows to achieve assemblies accurate and robust. It is essential for the safety and performance of vehicles.

Through this blog, I will guide you in the mastery of this technique. I’ll discuss the necessary equipment, the methods of surface preparation, and best practices to get professional results.

Whether you’re a beginner or an expert, you will find here practical tips for perfecting your art of welding points. You maximizing your bodywork repairs.

TIG, MIG MAG, MMA, SPOT WELDING AND STUD WELDING FOR DENT REPAIR

Trusted and verified affiliates links

1. Presentation of the spot welder or spot welding.

The spot welding, spot welding, or spot welder is a welding method for electrical resistance. It primarily serves the automotive industry to assemble metal parts, rapid, and sustainable. This technique consists of applying a high pressure, and an electrical current of high intensity two or more sheets of metal stacked.

The electrical resistance at the interface of metals generates enough heat to melt locally. It thus forms a weld solid once cooled.

The main use of the spot welding in the automotive industry lies in the assembly of the body panels and metal structures of vehicles. This method is appreciated for its speed and efficiency. It allows thousands of welding points in a single day of production. It also offers a great precision, which is essential to maintain the tight tolerances required in the automotive manufacturing.

2. Highlighting the benefits of the spot welding.

The advantage of the welding points is its ability to create seals robust. This does not require additional materials. In addition, this method minimizes the distortion of the metal parts. This is crucial in order to preserve the structural integrity and the aesthetics of the vehicle.

The spot welding is a key technology in the automotive industry. It allows us to produce vehicles that are safe, reliable and esthetically pleasing. I will share in-depth knowledge and practical advice on how to master this technique. Whether you are a professional body or an avid hope improve your knowledge in welding.

Speed

The spot welding is extremely fast. This makes it a technique of choice in environments of large-scale production, such as the automotive industry. Each weld takes only a few milliseconds to a few seconds, depending on the thickness and type of metal. This speed allows you to make thousands of welding points per day. It increases the efficiency and productivity of assembly lines.

Precision

The accuracy of the spot welding is another major asset. The welding machines have sophisticated controls. They regulate the pressure and the electric current with a high accuracy. This allows you to position the solder points exactly where they are needed, ensuring a perfect alignment of the parts. This precision is essential. It maintains the strict tolerances required in the automotive manufacturing. Small errors should not affect the quality and safety of vehicles.

Quality of welds

The quality of welds by points is high. This method produces welds are strong and durable, and are capable of bearing heavy loads. The heat is localized. This minimizes the distortion of the metal parts. This preserves the structural integrity of the assembly. In addition, the weld is esthetically discreet. This is important for the sewing visible on the car bodies.

3. Economic interests of the spot welding.

The welding points is of economic interest to be significant. Including reduction of the labour costs of work and materials. Here is a detailed overview of these economic benefits :

Reduction of costs of implementation

- Automation of the process : The welding is easily automatable. Welding robots can perform welds accurate and fast without the need for human intervention constant. This reduces the need for labour-skilled labor, thus lowering labour costs.

- Increased efficiency : the speed of The welding points can significantly reduce the time required to assemble the metal parts. This efficiency translates to higher productivity. It allows to produce more vehicles or components in less time. This reduces the cost of production.

- Less training required : Compared toother welding techniques, welding by points requires less training. Employees can be quickly trained to use the machines of welding points. This reduces the cost of training.

Reduction of material costs

- Absence of filler materials : compared to other welding methods that require filling materials (such as rods or wires for welding), welding by points does not require any extra material. This directly reduces the cost of materials.

- Less waste : The spot welding generates very little waste. The heat is concentrated only to the solder points. This minimizes the loss of material. This efficiency material helps to reduce the costs associated with waste and recycling excess materials.

- Savingenergy : The machines welding consume relatively little energy compared to some of the other welding techniques. The consumption of lower energy translates into reduced energy costs. This is particularly advantageous in large industrial facilities.

By integrating the welding points in the manufacturing process, companies can achieve substantial savings in laborand materials. This method contributes to the production cycles shorter, more efficient use of resources and a decline in operating costs overall. In a sector such as the automotive industry, where margins are often tight, these savings can significantly improve the profitability and competitiveness of enterprises.

4. Environmental benefits of the spot welding.

The spot welding has several environmental benefits, including the reduction of emissions of smoke and gas pollutants. Here is a detailed analysis of these benefits :

Reduction of the emissions of smoke and gas pollutants

- Absence of filler materials : Unlike some other welding techniques, such as welding, the arc, the welding does not require filler materials such as rods or wires. These filling materials may generate fumes and gases pollutants when burned. The absence of these materials in the welding points reduces directly the emissions of smoke and harmful gases.

- Process own : The spot welding mainly uses the heat generated by electrical resistance to melt and join metals. This process generates very little smoke and particles, because it does not produce an open flame or combustion of additional materials. Therefore, the air in the work environment remains clean, which is beneficial to the health of workers and the environment.

- Emissions limited gas : The spot welding produces less gas pollutants, such as ozone and oxides of nitrogen, compared toother welding processes using electric arcs or fuels. The reduction of these emissions contributes to a lower environmental impact and improves the quality of theair in industrial facilities.

Less consumption of energy

- Energy efficiency : The spot welding is a process with high energy. The heat is only at the interface of the metals to be welded. This efficiency reduces the consumption of energy compared to other welding methods more efficient, reducing the carbon footprint of welding operations.

Reduction of metal waste

- Less deformation : The localized heat of the welding points minimizes the deformation of metal parts, which reduces the need for rework or replace damaged parts. This translates to a reduction of metal waste and a more efficient use of resources.

- Optimization of the materials : minimizing losses of materials and generates very little waste, the welding points allows more efficient use of metals, thus reducing the environmental impact associated with the extraction and production of new materials.

The adoption of the welding points in the manufacturing process contributes not only to economic gains, but also to have significant environmental benefits. The reduction of smoke emissions and of pollutant gases, the lower consumption of energy, and the optimization of the materials are all factors that make this process more respectful of the environment. By improving the energy efficiency and minimizing waste, the welding points helps industries to reduce their environmental footprint while maintaining high standards in production and quality.

5. Importance of spot welding.

The spot welding or spot welding, plays a crucial role in the automotive body repair.

Here are the main reasons why this technique is so important in this field :

Restoration of the structure of origin

- Maintenance of the structural integrity : The spot welding is able to recreate the welds of origin of the vehicle, which is essential for maintaining the structural integrity. The solder points added to restore the strength and rigidity of the body panels, to ensure the security and performance of the vehicle after repair.

Quality of the repair

- Welds clean and discrete : The spot welding produces welds are clean, accurate and unobtrusive, which is crucial for the finishes of the body. This helps to keep the esthetics of the vehicle by minimizing the visible signs of repair.

- Less thermal distortion : The heat generated by the spot welding is concentrated only at the place of the weld. This reduces thermal distortion of the metal panels. This precision makes it possible to preserve the shape and dimensions of original parts, avoiding the strain and the additional adjustments.

Efficiency and speed

- Quick repair : The spot welding allows you to perform welds in a few seconds, which speeds up the repair process. This speed is particularly beneficial in repair shops, where time is a crucial factor for the profitability and customer satisfaction.

- Automation possible : In some body shops advanced, the use of spot welder atomatised allows you to standardize and further accelerate the repair process, ensuring consistent results and high-quality.

Compatibility with modern materials

- Adaptability to the modern materials : The modern vehicles use a variety of materials, including high-strength steels, and alloys of aluminum. A spot welder is compatible with these materials, allowing repairs to be effective and appropriate for the vehicles of the latest generation.

Cost and efficiency

- Cost reduction : minimizing the need for filler materials and reducing repair time, the spot welding helps to reduce the overall cost of repair. This allows body shops to offer high-quality services at competitive prices.

Safety standards

- Standards compliance safety : many vehicle manufacturers specify the welding points for bodywork repairs to meet the standards of security and guarantee of vehicle. Use this technique ensures that the repairs are in accordance with the manufacturer’s specifications, thus preserving the security and the value of the vehicle.

The welding points is essential in the repair body for several reasons : it helps to maintain the structural integrity and esthetics of vehicles, speeds up the repair process, reduces costs, and ensures compliance with the safety standards of the manufacturers. Thanks to his precision, efficiency and compatibility with modern materials, the spot welding is an indispensable technique for repair shops, seeking to provide repairs of high-quality and reliable.

4. Operation of the spot welding.

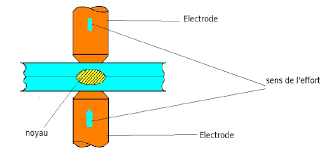

Principle of operation of a post welding points

The spot welding, is a welding process by electrical resistance. It’s used to join parts thin metal by applying pressure and an electric current high points located. Here’s a detailed explanation of working principle :

The metal parts should be cleaned and aligned properly. It is essential that the surfaces are clean to ensure a good electrical conductivity and weld solid.

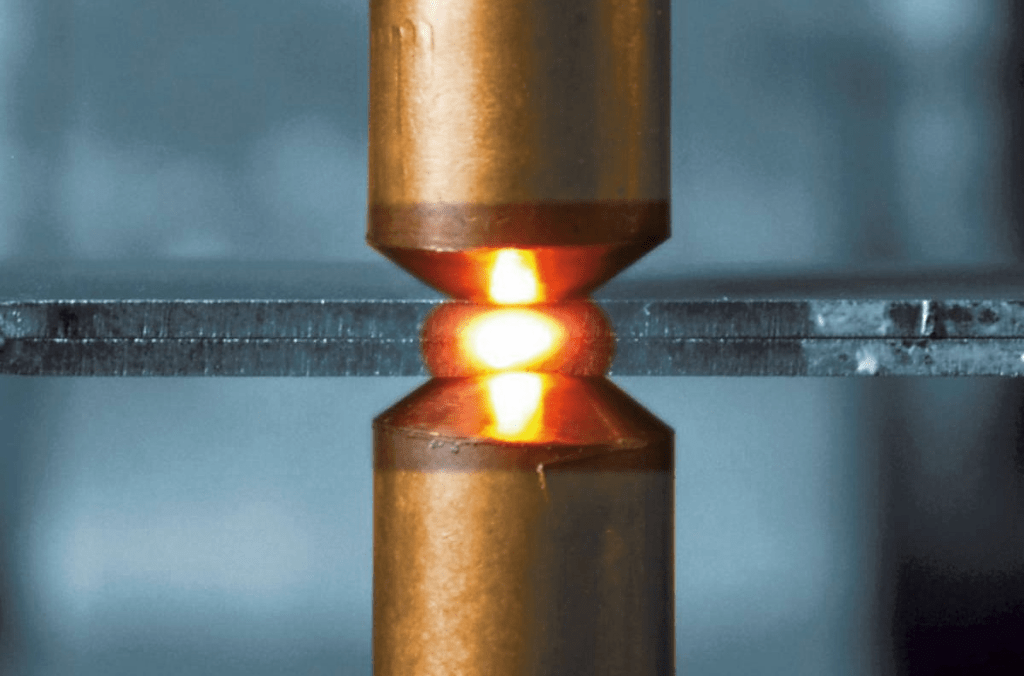

The metal elements superimposed are placed between two copper electrodes, generally cylindrical in shape. The electrodes are designed to concentrate the pressure and electric current in a small area.

An electric current of high intensity sapplied briefly through the electrodes. The electrical resistance at the interface of the metal parts generates an intense heat that melts locally as the metal at theinterface of the parts.

This heat generated by the electrical resistance to the melting of metallic surfaces in contact, create a nucleus of fusion. The pressure exerted by the electrodes keeps the pieces in place as the molten metal solidifies, forming a weld strong and durable.

Once the molten metal sis solidified and the weld is formed, the electric current is cut off. The electrodes are removed and leave a point of welding is robust.

Operation diagram

Here is a schematic description of the operation of welding points :

Electrodes : Represented by the cylindrical bars of copper to the top and bottom.

Metal parts : Two metallic sheets overlapping between the electrodes.

Welding Point : melting Zone where the metal parts are joined.

The spot welding is an effective and reliable technique to assemble metal parts, particularly in production environments on a large scale as the automotive industry.

5. The various components of the spot welding.

The welding points, or spot welder involves several key components. Each element plays a vital role in the welding process. Here is a detailed overview of the different components of a spot welder and their specific role :

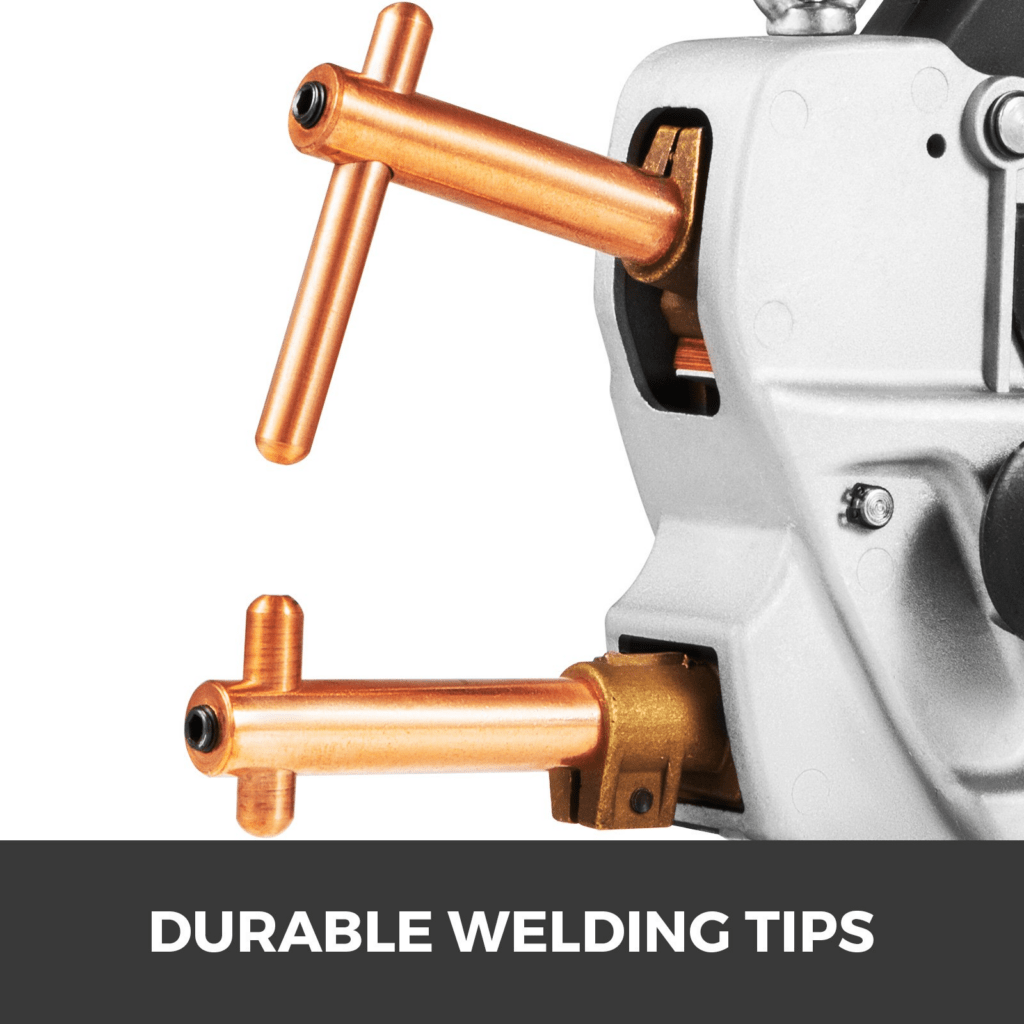

1. Electrodes

The electrodes are crucial components in the spot welding. They are usually made of copper or copper alloys due to their high electrical and thermal conductivity.

- Role :

- Transmit the electrical current to the parts to be welded.

- Apply the pressure needed to hold the parts in contact during welding.

- Lead the heat generated by electrical resistance to melt the metal at the interface of the parts.

2. Transformer

The processor is responsible for converting the electrical power supply of low voltage and high current required for the welding process.

- Role :

- Reduce the high voltage of the power supply to a lower voltage.

- Increase theintensity of the current to provide the energy necessary to power the resistance welding.

3. Controller

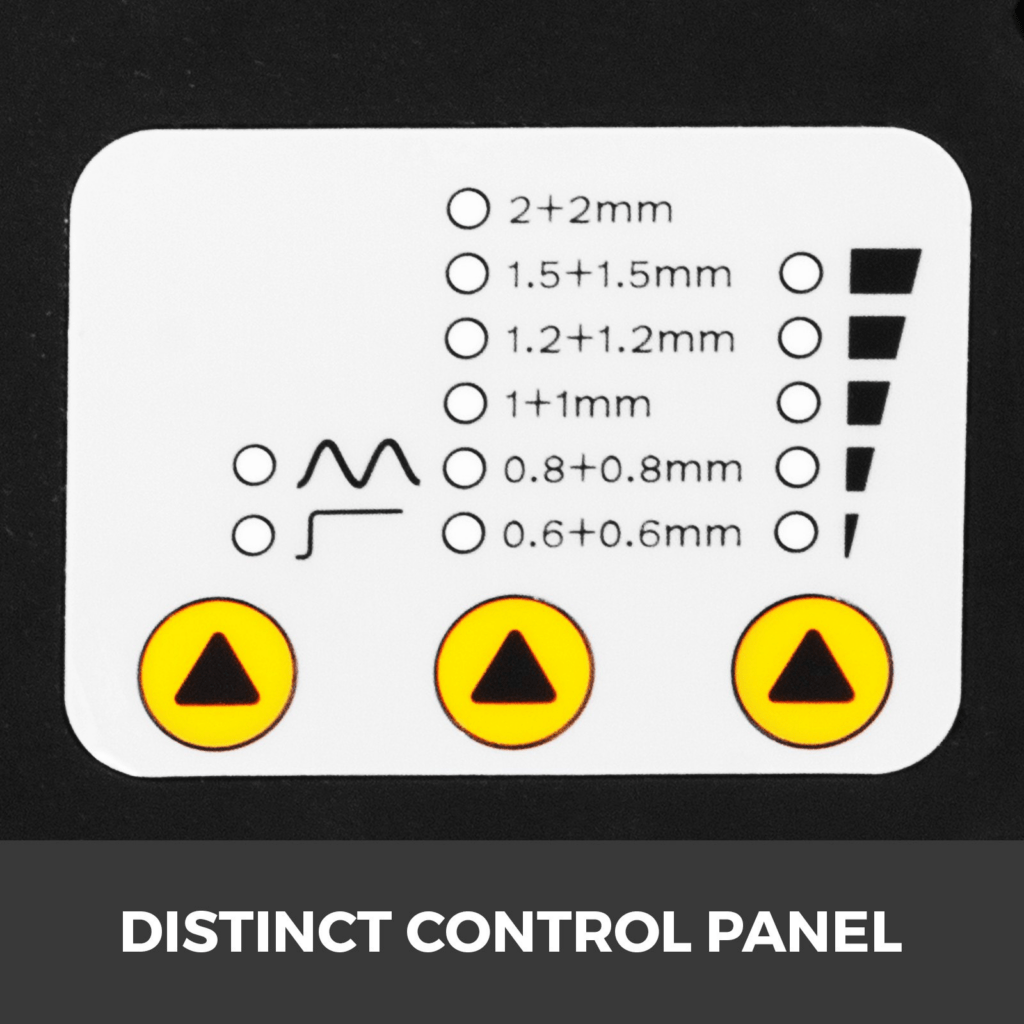

The controller is an electronic device that regulates the welding parameters, such as current, the welding time and pressure applied by the electrodes.

- Role :

- Regulate the time of the passage of the current for each welding point.

- Adjust the intensity of the current as a function of the characteristics of the materials to be welded.

- Control of the pressure applied by the electrodes to ensure a uniform welding and quality.

4. Arm welding

The arms of welding are the mechanical components that support the electrodes and apply the necessary pressure on the parts to be welded. They may be fixed or mobile, depending on the type of machine.

- Role :

- Support and position the electrodes correctly on the parts to be welded.

- Apply and maintain a constant pressure during the welding process.

5. Cooling system

The cooling circuit is often built into the machines of welding points to dissipate the heat generated during the welding process.

- Role :

- Cool the electrodes to prevent overheating and prolong their life.

- Maintain a stable operating temperature in order to ensure the quality of the welds.

6. Control system, pneumatic or hydraulic

This system is used to apply and control the pressure exerted by the electrodes on the parts to be welded.

- Role :

- Provide the force necessary to press the electrode against the metal parts.

- Check the pressure in a precise manner to avoid deformation of the parts and ensure high quality welds.

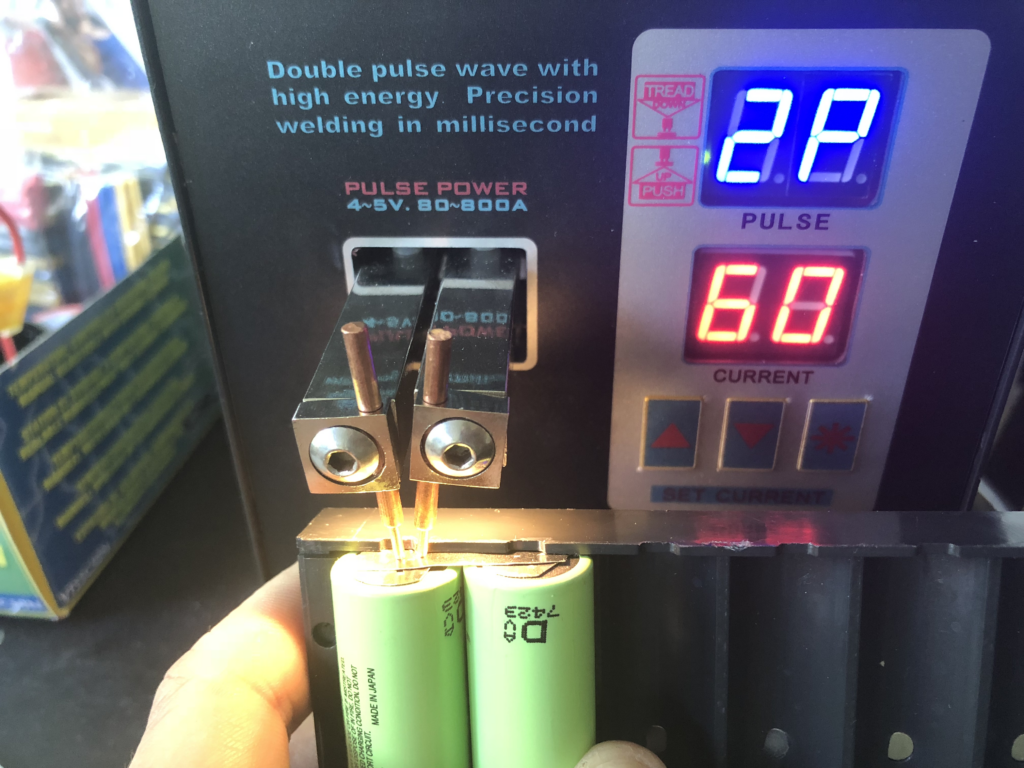

7. User Interface

The user interface includes controls and displays, allowing the operator to configure and monitor the welding process.

- Role :

- Allow the operator to adjust the welding parameters (current intensity, welding time, pressure).

- View the real-time information on the state of the machine and the welding performance.

8. Power supply

The power supply provides the energy necessary for the functioning of the whole system of spot welding.

- Role :

- Feed the transformer to generate the welding current.

- Provide the energy needed to power control systems, and cooling.

Each component of a spot welder, therefore, plays a vital role to ensure the welding efficient, accurate, and of high quality.

The electrodes transmit the power and apply the pressure, the transformer converts the electrical power supply, the controller regulates the welding parameters, and the arms of welding position and press the electrodes.

The cooling system maintains the proper temperatures, and the system of pneumatic or hydraulic handles the pressure.

Together, these components work in synergy to achieve welds that are robust and reliable, which is essential in industrial applications such as automotive manufacturing.

6. Different variables of spot welding.

In spot welding, the user can control several variables that are essential to ensure high quality welds and adapted to the specific requirements of materials and parts to assemble. The main variables controllable power, time and pressure.

Here’s a detailed explanation of each of these variables and their importance :

1. Power (welding Current)

- Definition : The power, often measured in amperes, is the electric current supplied through the electrodes to generate the heat needed for soldering.

- Importance :

- Heat generation : A higher current generates more heat is required to melt the metal at the points of contact.

- Adaptation to materials : Different materials and thicknesses of metal that requires levels of power that are specific. For example, stainless steels may require a higher current than the steels sweet.

- Control : The user can adjust the current as a function of the characteristics of the materials and the requirements of the solder, to avoid overheating or insufficient weld.

2. Duration (welding Time)

- Definition : The amount of time, often measured in milliseconds or seconds, is the time during which the electric current is applied across the electrodes.

- Importance :

- Fusion appropriate : A length of suitable welding ensures that the metal at the interface substantive enough to form a weld solid.

- Accuracy : A welding time too long may cause overheating and a distortion of the parts, while too short of a time may result in a weld low.

- Control : The user sets the duration of welding as a function of the thickness of the metal and thermal properties of materials.

3. Pressure (Force applied by the electrodes)

- Definition : The pressure, measured in Newtons or in Pascals, is the force applied by the electrodes to maintain metal-to-metal contact during the welding.

- Importance :

- Contact intimate : A sufficient pressure to ensure intimate contact between the parts to be welded, reducing the electrical resistance at the interface and facilitate the formation of a weld solid.

- Prevention of faults : too high A pressure can deform the parts, where as insufficient pressure can lead to weak welds or incomplete.

- Control : The user adjusts the pressure as a function of the mechanical properties of the materials and the geometry of the parts to be welded.

4. Relationship between the variables

- Interaction : These variables are interconnected. For example, increasing the current, often requires an adjustment of the length and the pressure to avoid the defects of solder.

- Optimization : in order to obtain a weld quality, it is essential to find the optimum balance between power, time and pressure. Precise adjustments and tests are usually necessary to determine the ideal parameters for a given application.

The precise control of the power, duration, and pressure is crucial in the spot welding to ensure the welding robust and of high quality. These variables allow the user to adapt the process to the specific requirements of materials and parts to assemble, ensuring optimal results and reliable. An understanding and careful management of these parameters are essential for the success of the operations of spot welding in industrial applications varied.

7. Applications of the spot welding

The spot welding (spot welding) is widely used in the automotive industry due to its rapidity, accuracy, and its capability to create welds, solid and durable.

Here are the most common applications of this technique in this sector :

1. Repair sheet

Auto body repair : The spot welding is commonly used to repair the body panels are damaged. It allows you to replace sections of sheet metal without affecting the surrounding areas due to the localized heat generated by the process.

Alignment and fixation : The plates are often aligned and temporarily fixed by solder points before you welded continuously. This ensures accurate alignment and a temporary fixation robust.

2. Strengthening of structures

Strengthening of frameworks : The welding points is essential to strengthen the frameworks of vehicles, including structural parts, such as the amounts of the doors, rails, and ties. These welds ensure the rigidity and robustness of the structures.

Bars anti-intrusion : The bars anti-intrusion into the doors of the cars, that increase safety in the event of a side-on collision, are often fixed by spot welding to ensure a solid foundation, and reliable.

3. Assembly of parts

Assembly of sub-components : many sub-structures, automobiles, such as the seats, fuel tanks, and the panels are assembled using the welding points. This includes the securing brackets, reinforcements, and ofother structural components.

Body panels : The main body panels, such as roofs, hoods, and doors, are often assembled with the help of this technique. The welding points allows you to assemble these panels for fast and accurate while maintaining a clean finish.

Chassis and sub-frameworks : the chassis of The vehicle and the sub-frameworks, which support the engine and of other critical components, are often collated using the welding points. This ensures a high structural integrity and the ability to withstand large loads.

4. Construction of crates of vehicles

Assembly of the box : The vehicle body (or body-frame integral) is often made up of many panels that are fused together by points. This includes the roof, the doors, the floor, and the side panels, all set to create a unified structure and durable.

Assembly of parts external : external components such as fenders, hoods, and trunk lids are often welded to ensure that they remain securely in place and precisely aligned with the rest of the body.

5. Attachment of accessories and internal components

Systems of fastening : fastening systems for internal, like the holders of the dashboard, the reinforcements of the seat and fixings, safety belt, are often welded by points. This helps to ensure that these critical components remain secure in the event of a collision.

Assembly of seat structures : frames automotive seats are assembled by spot welding to ensure sturdiness and durability maximum. This includes the mounting rails, brackets and adjustment mechanisms.

The spot welding is an indispensable technique in the automotive industry for its multiple applications. That it’s both repair sheets, build structures, or parts are joined together, this method allows you to create welds solid, precise and esthetic. Its use in the assembly, body panels, the strengthening of the chassis, and the mounting of the internal and external components demonstrates its crucial role in the manufacture and repair of modern vehicles. Thanks to its speed, its accuracy and its ability to produce high quality welds, the welding points remains a mainstay of the automotive industry.

8. Other potential applications of the spot welding.

The spot welder (spot welding) is a technique that is versatile and adaptable, being used not only in the automotive industry, but also in various other sectors. Here’s an exploration of its potential applications in the fabrication of sheet metal, the appliances, the aerospace and other areas, as well as its versatility in terms of materials and of thicknesses.

Applications in other areas

Assembly of metal structures : The spot welding is used to assemble metal structures, light and medium, such as frames, mounts and housings of sheet metal.

Manufacture of metal furniture : metal furniture, such as cabinets, shelves and chairs, are often assembled with the help of this technique to ensure junctions strong and discrete.

Building industry : In construction, the welding is used to assemble components such as frames of doors, windows, and ventilation systems.

Household appliances

The spot welding is commonly used to assemble household appliances such as refrigerators, washing machines and ovens. This technique allows the setting of pieces of thin sheet metal with a high degree of accuracy.

Consumer electronics : The metal housings for televisions, computers and other electronic equipment are often welded to ensure fast, reliable manufacturing.

Assembly of cells of plane

Inaeronautics, the welding is used to assemble the parts of the cell of the aircraft, such as the panels of the fuselage sections and wing. This method allows you to create welds mild and strong.

Repair of components of air : The spot welding is also used for the repair and maintenance of aircraft, to determine quickly the parts damaged or worn.

Battery manufacturing

The cells of batteries, especially lithium-ion batteries for electric vehicles and electronic devices, are often welded by points, to connect the metal strips.

Medical equipment : medical devices, such as beds of hospitals, carts, and boxes of medical devices, use the spot welding joints precise and sterile.

The spot welder is capable of welding a variety of materials, which makes it extremely versatile :

Steel :

Commonly used to weld plates of mild steel, stainless, and high-strength steels.

Aluminum : Used for welding alloys of aluminum, although adjustments of parameters (such as current and duration) are necessary because of the high thermal conductivity of the aluminum.

Copper : Solder copper alloys requires a precise management of the current and the pressure to avoid overheating.

Nickel and other alloys : welding points is also suitable alloys for specific, commonly used in the aerospace and industrial applications specialist.

Adaptability to various thicknesses of the spot welder can be adjusted for welding materials of different thicknesses :

Thin sheet metal :

The spot welding is especially effective for welding thin sheet metal (up to approximately 3 mm of thickness), thanks to its ability to generate localized heat and apply a precise pressure.

Thicker materials : Although less common, welding machines points powerful can be used for welding thicker materials, by adjusting the current and length of welding to ensure a merger adequate.

Body panels : Stud welder

The spot welding is a technique that is extremely versatile and adaptable, being used in a variety of sectors from the automotive industry to the manufacture of sheet metal, the appliances, and the aerospace. Its ability to weld a wide range of materials, including the steel, the aluminum, copper, and various alloys, as well as varying thicknesses, in fact a method of welding a very flexible and efficient. This versatility allows to achieve assemblies robust and precise, responding to the strict requirements of many industrial and commercial applications.

9. Choose a spot welder

Tips for choosing a spot welder suitable for your needs, taking into account factors such as the budget, the intended applications and technical specifications.

Choose the spot welder suitable for your needs involves taking into account several factors, including budget, the intended applications, and specific technical characteristics. Here are a few tips to guide you in this process :

1. Defining the requirements and intended applications

- Type of materials : Identify the types of materials that you are going to weld (steel, aluminum, copper, etc). Some spot welders are better suited to certain materials because of their conductivity and resistance.

- Thickness of the material : Determine the thickness of the material you will weld. Make sure that the machine can generate enough current to weld effectively thicknesses provided.

- Volume of production : If you plan to weld in large quantity, an industrial machine more robust and fast will be necessary. For more casual, a machine more simple and less expensive, it might be enough.

2. Budget

- Initial cost : Compare the initial costs of the different machines. Industrial machinery and more sophisticated will be more expensive, but can offer advanced features that justify theinvestment.

- Maintenance costs : Consider the costs of maintenance and replacement of parts (such as electrodes) for each machine. A machine is less expensive, can have maintenance costs higher in the long term.

- Energy efficiency : Look for machines that are energy efficient to reduce the costs of operating.

3. Technical characteristics

- Power and current capability : Make sure that the machine can provide the necessary current for the materials and thicknesses that you are going to weld. A machine with a processor powerful is often required for thicker materials or resistant.

- Pressure control : Look for machines with precise control of the pressure to ensure high quality welds, especially for material purposes or in applications requiring a high level of precision.

- Welding time : Check that the machine allows a precise adjustment of the welding time, which is essential to adjust the duration of the current as a function of the materials used.

4. Ergonomics and ease ofuse

- User Interface : Choose a machine with a user interface that is intuitive and easy to use. Commands clear and a digital display that can simplify the adjustment of the parameters.

- Mobility and size : If you have constraints of space or if you need to move the machine, opt for a compact and mobile.

5. Reliability and durability

- Brand and reputation : Look for brands that are recognized for their reliability and after-sales service. The feedback of the users and the professional recommendations can be very useful.

- Warranty and technical support : Check warranty terms and conditions and the availability of technical support. A good coverage of the guarantee, and a responsive support may be crucial in the event of problems.

6. Additional features

- Cooling systems : A good cooling system can prolong the life of the electrodes and of the machine, especially for cycles of intensive production.

- Flexibility of the electrodes : The ability to easily change the electrodes for different applications can be a significant advantage.

- Automation and integration : For advanced industrial, consider machines that are compatible with automated systems or can be integrated in production lines, robotic.

Choose the spot welder suitable for your needs requires a thorough assessment of your applications, your budget, and the technical characteristics of the available machines. Taking into account these factors, you can select one machine which offers the best combination of performance, reliability, and cost, while responding to your specific welding requirements. Look for machines of well-known brands, read user reviews, and consult experts to ensure you are making the wisest choice.

Different types of spot welder available on the market, such as portable models, stationary models and the models robot.

On the market, there are different types of spot welders are designed to meet a variety of needs and applications. Here is a view of all the main types of spot welders available :

1. Spot Welders Portable

The spot welders, portable, compact, lightweight, and often powered by a source of portable energy such as batteries or a standard power supply. They offer great mobility and are generally used for welding on site or in tight spaces.

Applications : automotive Repair, on the ground, assembly, sheet metal, mild, maintenance and repair.

2. Spot Welders Stationary

The spot welders stationary machines are larger and more robust designed to be permanently installed in a workshop or production line. They offer a power and a capacity of welding more important than portable models.

Jobs : Lines of industrial production, auto repair shops, manufacturing of sheet-metal working, assembly of metal structures.

3. Spot Welders Robotic

The spot welders robot are integrated to industrial robots, programmable to automate the welding process. These systems offer great precision, high repeatability and increased productivity, especially for welding applications with a high rate.

Applications : automated production Lines, automotive manufacturing, aerospace, electronic industry.

4. Spot Welders for Manual Control

The spot welders for manual control are machines that require a direct intervention of the operator to place the electrodes and trigger the process of welding. They are often used for welding operations, and simple little large.

Jobs : automotive repair shops, maintenance, manufacturing on a small scale.

5. Spot Welders Automatic

The spot welders automatic are equipped with control systems, programmable to automate the welding process, including the positioning of the electrodes, the adjustment of the welding parameters and the trigger of the welding cycle.

Applications : automated production Lines, industrial manufacturing, assembly of parts in series.

6. Spot Welders with Medium Strength and High-Frequency

The spot welders with medium strength and high-frequency use, respectively, of the common welding of medium and high frequency to achieve welds. These machines offer specific advantages in terms of speed of welding, weld quality and thermal control.

Applications : Welding of special materials, applications that require a high-productivity, an assembly of delicate parts.

The choice of the type of spot welder will depend on the specific needs of your application, your budget, mobility requirements, and the level of automation desired. Whether for work, auto repair, on site, welding operations, industrial automated or precision work in an artisan’s workshop, there is a spot welder suitable for every situation.

Specific brands and models of spot welder industrial in terms of reputation and performance.

There are several brands and models of spot welders deemed to be on the market, offering a range of performance and features to meet a variety of needs in welding. Here are some of the most trusted brands and some of their models most popular :

1. Miller Electric

Miller Electric is renowned for its welding machines of high quality, offering a combination of performance, reliability and innovation.

- Popular models :

- Miller Spot Welders Series : This series includes a range of models, including the Miller LMSW-52T and the Miller LMSW-52, offering versatility and reliability to the applications of spot welding.

2. Lincoln Electric

Lincoln Electric is another reputable brand, offering a wide range of welding machines, adapted to different industrial needs.

- Popular models :

- Lincoln Electric Power MIG 210 MP : Although primarily a post-weld MIG, it can also perform welds by points with special electrodes, providing versatility for a variety of welding applications.

- Lincoln Electric Power Wave S350 : This model offers advanced performance for the welding points and is often used in industrial environments demanding.

3. Pro Spot International

Pro Spot International is specialized in the equipment of welding and auto repair, offering high-end solutions for body shops.

- Popular models :

- Pro Spot i4s : This spot welder is designed specifically for repairs of car body, offering a high-precision, versatility, welding, and ease ofuse.

4. Sunstone Welders

Sunstone Welders offers a variety of spot welders high quality, including portable models and systems for automated welding.

- Popular models :

- Sunstone CD Welders Series : This series includes a range of spot welders capacitor discharge, providing great power and precision of high welding for a variety ofindustrial applications.

5. Stryker

Stryker is specialized in the equipment of welding and body repair, offering solutions that are robust and reliable for the automotive repair industry.

- Popular models :

- Stryker Cheetah Xi : This spot welder is designed to deliver high performance and ease of use for the repairs of car body.

6. HBS Stud Welding

HBS Stud Welding is specialized in the equipment of welding and welding studs, offering high-quality solutions for a variety of industrial applications.

- Popular models :

- HBS S30i : This spot welder offers great power and precision of high welding for a variety ofapplications of spot welding.

These brands and models represent some of the spot welders the most renowned on the market, offering a combination of performance, reliability and features to meet a variety of needs in welding. Before making a choice, it is recommended to compare the technical specifications, features and user reviews to find the spot welder that best suits your specific needs.

10. Security and maintenance of spot welder.

Security issues related to the practice of spot welding such that the risk of burns, dshock, and dinhalation of the fumes.

The use of the spot welder has some risks to the security, and it is essential to take appropriate precautions to minimize these hazards. Here are some of the issues of the most common security related to the use of the spot welder, as well as measures to prevent :

1. Risk of burns

Causes : The electrodes and the metal parts can become extremely hot during the welding process, which can cause burns if they are accidentally touched.

Prevention :

Use insulating gloves and appropriate protective clothing to protect the skin from burns.

Avoid touching the electrodes and the metal parts during and after the welding process, up to this that they have cooled down.

2. Risk of electric shock

Causes : The spot welder uses high voltage electricity to generate the heat necessary for the process of welding, which presents a risk of electric shock if the appropriate precautions are not taken.

Prevention :

Make sure that the machine is properly grounded to avoid electric shock.

Avoid touching the metal parts of the machine while it is under tension.

Use tools and electrical equipment in good condition and meet safety standards.

3. Risk of inhalation of the fumes

Causes : welding may produce fumes and toxic fumes during the fusion of metals, which can be harmful if it is inhaled.

Prevention :

Work in a well-ventilated area to remove fumes and toxic fumes.

Use a respirator appropriate, in particular when welding materials coated, or galvanized.

Avoid breathing directly on fumes by working in an area where the extraction of fumes is enabled.

4. Risk of injuries related to the equipment

Causes : The electrodes mobile and moving parts of the machine may present a risk of injury if they come into contact with hands or other parts of the body.

Prevention :

Make sure that the appropriate safeguards, such as the protective covers are in place during the operation of the machine.

Do not touch the moving parts of the machine while it is running, and turn the power switch off before conducting any maintenance or adjustment.

5. Risk of fire

Causes : The sparks generated during the welding process may cause a fire if there are flammable materials nearby.

Prevention :

Working in an area cleared of all flammable material and the use of protections fire retardants if required.

Have a fire extinguisher nearby and know its use in cases of emergency.

6. Training and awareness

Make sure that all operators of spot welder have received appropriate training on safety procedures and are aware of the potential risks associated with the use of the equipment.

Encourage security awareness and culture of reporting safety concerns in the workplace to promote a safe work environment.

Safety is an absolute priority in the use of the spot welder. By identifying and mitigating potential risks, by adopting safe work practices and providing training to the operators, it is possible to minimize the accidents and ensure a safe working environment and healthy.

Instructions for the safe and responsible use of the spot welder.

For safe and responsible use of the spot welder, it is crucial to follow these instructions basic safety :

1. Training and skills

Make sure that you receive proper training on the use of the spot welder before use.

Familiarize yourself with the manual of use of the manufacturer and follow all instructions provided.

2 . Personal Protection

Always wear personal protective equipment (PPE) appropriate, including insulated gloves, safety glasses, work wear heat-resistant safety shoes.

3. Inspection of the equipment

Make sure that the spot welder is in good operating condition for use. Be sure that there is no apparent damage or missing parts. Make sure that the machine is properly grounded to avoid the risk of electric shock.

4. Preparation of the work area

Work in a well ventilated area to remove fumes and toxic fumes.

Keep work area clean and clear of any flammable materials or bulky.

5. Use of the equipment

Never modify or manipulate the settings of the machine during its operation.

Only use electrodes, and accessories recommended by the manufacturer.

Do not touch the metal parts of the machine while it is under tension. Make sure that the appropriate safeguards, such as the protective covers are in place during the operation of the machine.

6. Handling of metal parts

Handle metal parts with caution, because they may be extremely hot during and after the welding process.

Use pliers or tools to handle hot parts and prevent burns.

7. Monitoring and maintenance

Carefully monitor the machine during operation and stop it immediately in case of a problem.

Regularly perform the maintenance and maintenance of the machine according to the manufacturer’s instructions.

8. Fire suppression

Keep a fire extinguisher nearby, and make sure you know how to use it in case of emergency.

Be aware of the risks of fire, and keep a constant vigilance for the use of the spot welder.

By following these instructions basic safety, you can minimize the risks and ensure a safe and responsible use of the spot welder. Don’t forget that safety is always the number one priority when working with welding equipment.

Maintenance procedures, and recommended maintenance for the spot welder to ensure longevity and optimal performance.

To ensure the longevity and optimal performance of your spot welder, it is essential to follow maintenance procedures and of maintenance on a regular basis.

Here are a few recommendations for the maintenance of your spot welder :

1. Regular cleaning

Regularly clean the electrodes and the contact surfaces to remove any accumulation of dirt, dust, residue or solder.

Use a clean lint-free cloth with an appropriate solvent to clean the metal surfaces.

2. Checking electrical connections

Regularly check the electrical connections to ensure that they are clean, tight and free of corrosion.

Tighten the terminals and the connections if necessary to avoid problems of electrical conductivity.

3. Control electrode

Inspect the electrodes regularly for signs of wear, cracking or damage.

Replace the electrodes if they are worn or damaged to maintain the welding performance good.

4. Lubrication of moving parts

Lubricate the moving parts and the mechanisms of adjustment in accordance with the manufacturer’s recommendations.

Use a suitable lubricant to prevent premature wear and ensure a smooth operation of the machine.

5. Control of welding parameters

Check and calibrate regularly welding parameters, such as pressure, current, and duration of the welding process, to ensure high quality welds.

Readjust the settings if necessary depending on the materials and thicknesses to be welded.

6. Preventive Maintenance

Schedule inspections and maintenance preventative on a regular basis to detect potential problems beforethey become serious.

Follow the schedule of maintenance recommended by the manufacturer for each component of the machine.

7. Replace parts of wear and tear

Replace parts of wear and tear, such as electrodes, springs and insulators, depending on the intervals recommended by the manufacturer.

Use spare parts of origin to ensure the compatibility and performance of the machine.

8. Staff training

Make sure that the personnel responsible for the maintenance of the machine is properly trained and qualified to perform the required tasks safely.

Provide ongoing training on the procedures of maintenance to maintain staff skills up to date.

By following these maintenance procedures, and recommended maintenance, you can extend the life of your spot welder and to maintain its optimal performance. Regular maintenance helps to avoid unplanned outages, minimize the time of arrest and to ensure a safe and reliable operation of the machine.

Supplier of spot welder to get more information.

Here is a list of providers spot welders, including some of the leading manufacturers and distributors in the field. You can check out their web sites for more information on their products, services, and technical support :

Miller Electric

Web Site : Miller Electric

Products : Wide range of welding machines, including spot welders for industrial applications and bodywork.

Lincoln Electric

Web Site : Lincoln Electric

Products : spot Welding equipment, welding MIG/TIG welding, consumables and accessories.

Pro Spot International

Web Site : Pro Spot International

Products : Equipment, welding systems, auto body repair, accessories and consumables.

Sunstone Welders

Web Site : Sunstone Welders

Products : Spot welding portable and stationary systems, welding, capacitor discharge solutions for precision welding.

Stryker

Web Site : Stryker

Products : welding Equipment and auto body repair, including spot welders, high-performance.

HBS Stud Welding

Web Site : HBS Stud Welding

Products : Stud welding equipment, welding stud, welding systems for industrial applications.

ARO Welding Technologies

Web Site : ARO Welding Technologies

Products : Spot welding, robotic and manual, solutions of welding for the automotive industry and aeronautics.

TECNA

Web Site : TECNA

Products : Wide range of spot welders, weld guns for manual and automatic control systems of welding.

T. J. Snow Company

Web Site : T. J. Snow Company

Products :Machines for resistance welding, accessories and maintenance services.

Amada Miyachi America

Web Site : Amada Miyachi America

Products : Solutions of resistance welding, including spot welders for applications in medical, electronic and industrial.

These providers offer a variety of options in terms of capacity, technology, and price. By visiting their websites, you will be able to explore the technical specifications of their products, get quotes and contact their sales teams and technical support for more information.

Images of spot welder.

Testimonials from professionals of the automotive industry, which use the spot welder to the daily.

Here are a few testimonies of body builders that use of spot welders daily. These stories highlight the experience and the benefits perceived by professionals in their daily work :

Testimony of Christopher, Coachbuilder in AutoCase :

‘The spot welder has completely transformed the way we work. Before, some repairs, sheet metal took hours and required a lot of manual skills. With the spot welder, we can achieve welds, solid and precise in a few minutes. This allows us to not only save time, but also provide a better quality to our customers. The machine is easy to use and the settings are intuitive, which helps even the new members of theteam to be up and running quickly.’

Testimony of Sophie, Head ofworkshop at Body Centre :

‘The integration of the spot welder in our workshop has been a great investment. Not only is it dramatically reduces the time to repair, but it also improves the quality of the welds. We have seen a reduction in the feedback of customers to the problems of solder, which is a testament to the sturdiness and reliability of the repairs made. In addition, the equipment is very safe, provided you follow the basic safety instructions. Our technicians feel more confident in their work, knowing that they have the tools to be more effective.’

Testimony of Philippe, a Technician in the repair of body in QuickAuto :

‘I use the spot welder for several years, and I no longer be able to live without it. It is particularly useful for repairs on the body panels and sheet of structural reinforcement. The accuracy of the welds allows you to work on sensitive areas without the risk of damaging surrounding items. In terms of productivity, it is a major asset. I can complete repairs more quickly while maintaining a high level of quality. Therefore, I recommend strongly this tool to all professional body builders.’

Testimony of Isabelle, a Head of workshop at Prestige Body :

‘The spot welder is an indispensable tool in our workshop. We use on a daily basis for repairs and sheet metal work of assembly. What I particularly appreciate, is the simplicity of use and the consistency of the results. The welds are clean and solid, which is crucial for the safety and the esthetics of the vehicle. In terms of maintenance, the machine is relatively easy to maintain. This prevents the additional costs and time to stop prolonged.’

Testimony of Alain, the Owner of a Body Pro :

‘The purchase of a spot welder has been one of the best decisions for my business. We have been able to work much more without paying more and our employees. So we see a clear improvement in terms of speed and quality of repairs. The welds are clean and the customers are satisfied with the result. A machine is robust and reliable, and even with heavy usage, it continues to work perfectly. The spot welder has really optimized our process of work. It allows us to manage more vehicles in less time. This machine changed my life.’

Testimony of Jennifer, the Director of the Company Point Tech :

‘As director of Point Tech, the integration of welding machines points in our workshops has been a crucial step in our approach of optimization of the process and of continuous improvement of the quality of our services.

Before the adoption of these technologies, we use methods of welding to be more traditional. Although reliable, they often lack accuracy and required processing time to be longer. Our teams of technicians had to invest a lot of time and efforts to get the satisfactory results. This, in turn, increase our operating costs and on-time delivery for our customers.

The integration of machines, spot welding has truly transformed our way of working. These machines allow us to produce welds are precise and uniform in record time. They are particularly effective for applications of the body, where the precision and speed are essential. We opted for advanced models of Pro Spot International, known for their reliability and performance.

The results have been remarkable. Our technicians can now perform repairs more quickly while maintaining a high level of quality. This has led to a significant reduction in repair time. Our ability to manage a large volume of work has increased. Our customers have also noticed the difference, enjoying the speed and quality of repairs.

In addition, spot welders have improved the safety in our workshops. The risks associated with welding methods-traditional, such as burns and the smoke exposure, were significantly reduced. Our employees are now working in conditions that are more safe, which is essential for us.

Another significant advantage is the energy efficiency of these machines. They consume less energy welding methods are traditional. This helps reduce our carbon footprint and our energy costs. It is an important step towards our commitment to sustainability and environmental responsibility.

Thei ntegration of welding machines points in our workshops has been a strategic decision. It has improved our productivity, the quality of our services, and the safety of our employees. It is an investment that’s been proven to be extremely beneficial for Point Tech. I strongly recommend this technology to any company looking to modernize its welding process.’

Testimony of Sebastian, project manager at WeldSpot :

‘As a project manager at WeldSpot, I’ve had the opportunity to oversee the integration of spot welders in several body shops of our company. This initiative aimed to modernize our repair process and to improve the quality of services offered to our customers.

Before the integration of spot welders, our technicians used welding methods-traditional, often slower and less accurate. These methods required a lot of time and effort. This increased the cost of labour-work and extended repair time. In addition, the results were not always consistent, which can affect the satisfaction of our customers.

With the introduction of spot welders, we found significant transformation. These devices allow us to achieve welds clean and precise in record time. The ability of spot welders to generate welds constants without deformation of the adjacent panels is a major asset. This has not only improved the quality of repairs, but also reduces the need for touch-ups and reversals.

The benefits do not stop there. Thanks to the efficiency of spot welders, our technicians can now perform more repairs per day. This increases our operational capacity and reduced delays for our customers. The return on investment has been rapid. Savings in terms of time, labour and material costs have been substantial.

The integration of spot welders has also had a positive impact on the safety and security of our workshops. Risks associated with welding methods-traditional, such as burns, and the liberation of toxic fumes, have been greatly reduced. Our technicians work in conditions that are more secure, which is a priority for us.

In conclusion,

The integration of spot welders in our body shops has been a real success. The improvements in terms of quality as well as efficiency and safety are undeniable. I strongly recommend this technology to all companies of the body. They optimize their processes and provide a better quality service to their customers.’

These stories show that body builders appreciate the spot welder. Its ability to improve the efficiency, effectiveness, quality of welds, and the satisfaction of customers is important. The aspects of ease of use, precision and safety are also often highlighted. What are the key advantages of this equipment.

Case studies that demonstrate the practical benefits of the welding spot them in real life situations.

Here are several case studies that illustrate the use of a spot welder to straighten the car bodies. These studies show how this tool is used to improve the efficiency, accuracy and quality of the bodywork repairs.

Case study 1 : Repair Shop AutoTech

Context : AutoTech is an automotive repair shop specializing in the restoration of the damaged vehicle. They have recently incorporated a spot welder to improve their process of recovery of the body.

Problem : The workshop was having difficulties with the traditional methods of welding and straightening sheet metal. This resulted in welds of varying quality and repair time extended.

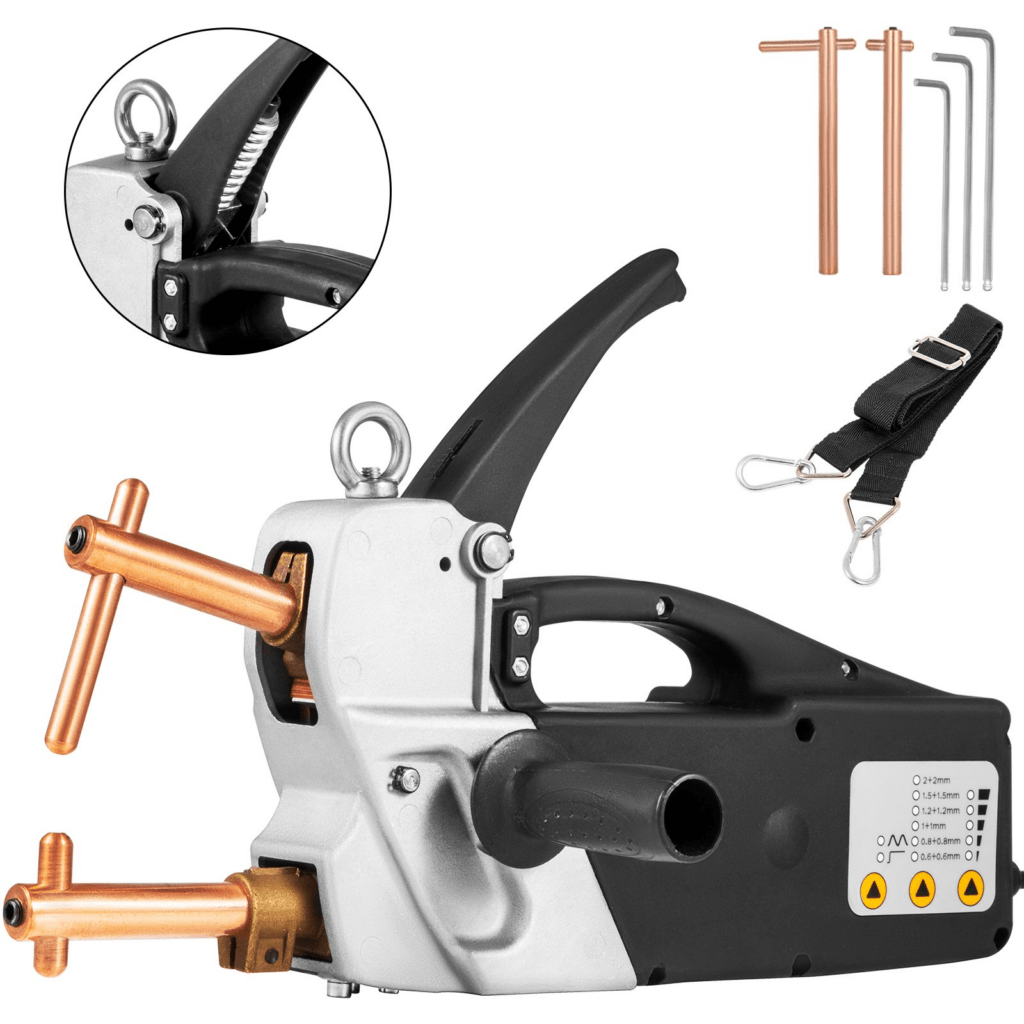

Solution : They have invested in a spot welder brand VEVOR. Its capabilities of welding, accurate and ease of use are appreciated.

Results : Reduction of Repair Time : The spot welder has helped reduce the time needed to straighten and weld body panels of 40 %. Technicians are now able to complete more repairs per day.

Quality improvement : The welds are cleaner and uniforms. This reduces the need of times and improves the aesthetics of the repairs.

Customer Satisfaction : customers have noticed the superior quality of the repairs. This has led to an increase of the recommendations and of the loyalty of the customers.

Case study 2 : Garage Pro Body

Context : Garage Pro Body is a family company that carries out bodywork repairs for over 20 years. They have incorporated a spot welder to modernize their repair techniques.

Problem : welding methods traditional created problems of deformation of the panels. They required additional finishes, increasing the time and cost of the repairs.

Solution : They chose a spot welder of the mark Pro Spot International, model i4s. Its advanced features and its ability to weld materials of different thicknesses are remarkable.

Results :

Increased accuracy : The spot welder allows you to weld specific points without distorting the adjacent panels. It is crucial to maintain the structural integrity of the vehicle.

Improved efficiency : The technicians can work more quickly. This thanks to the simplicity of use and the speed of the welds by points.

Reduced costs : Less welding materials are needed. The need for finishing work is considerably reduced. It thus lowers the overall cost of repair.

Case study 3 : Collision Centre AutoChoc

Context : AutoChoc is a center of a large collision, which processes a high volume of crashed vehicles. They have adopted advanced technology to stay competitive.

Problem : Their old method of welding the arc created welds of poor quality. This often required of times and lengthening the time of repair.

Solution : They have invested in a spot welder to the Lincoln brand Electric, model Power MIG 210 MP. It is able to produce welds by points with accuracy and efficiency.

Results :

Top quality Welds : welds performed with the spot welder is consistent and robust. This reduces the risk of structural failure.

Increased productivity : The cycle time of the reparations was reduced. This allows the workshop to handle more vehicles in less time.

Enhanced security : The risk of deformation of the panels, and overheating is minimized. This ensures better safety for technicians and repaired vehicles.

Balance sheet of the cases studied

These case studies show that the integration of a spot welder in an auto body shop can offer several significant advantages :

Efficiency and Productivity : The repair time are considerably reduced. This allows workshops to deal with more vehicles and to increase their operational capacity.

Quality of Repair : The welds are clean, accurate and consistent. This improves the appearance and strength of the repairs.

Customer Satisfaction : The improved quality of repairs translates into increased satisfaction of customers. This increases the recommendations and loyalty.

Reduction of Costs : The costs of materials and labourforce are reduced. Thanks to a more efficient use of resources and the reduction of occasions and finishing work.

By integrating spot welders repair shops to improve their repair process. They also offer a better service to their customers while reducing their operational costs.

Glossary of technical terms related to the spot welding to help readers better understand the subject.

Glossary of Terms Relating to Welding and Repair in the Auto Body :

Has

Alloy : Mixture of two or more metals, or of a metal and of a different element, designed to improve certain properties.

Boot : the Beginning of the welding process where the arc is established.

B

Ring : metal Ring used to strengthen the electrodes or to fix parts together during welding.

Noise d’arc : The sound emitted by theelectric arc during welding.

C

Scale : iron Oxide formed on the surface of the metal during heating, often removed before welding.

Coulure : Deformation of the base metal caused by excessive heat during welding.

D

Deformation : Changes in size or shape of the weldment due to heat applied.

Weld time : Time during which the electrical current is applied to the electrodes to conduct welding.

E

Electrode : Component conductor by which the electric current enters and exits the workpiece to be welded.

Welding energy : the total Amount of heat applied during the welding process.

F

Fusion : the Transformation of materials in a liquid state under theeffect of heat to form the weld.

G

Gouging : a Technique used to remove the metals unwanted or damaged prior to re-welding.

Droplet : a Small particle of molten metal is transferred from the electrode to the work piece during welding.

H

Height of soldering : Distance between the surface of the workpiece and the surface of the weld.

I

– Intensity : Electric current measured in amperes that is used in the welding process.

L

Line of fusion : the Area in which the base metal and the metal of the weld mix and solidify together.

Metallic bond : a Type of chemical bond formed during welding that ensures the cohesion between the metal atoms.

M

Metal dintake : a Metal added in the melt to form a weld.

Casting welding : Formation of the weld where it solidifies after fusion.

O

Oxidation : The reaction of the metal with the oxygen, forming oxides often undesirable on the surface of the parts to be welded.

P

Pressure : Force applied by the electrodes to hold the parts together during welding.

R

Resistance : Property of a material sopposition to the passage of electric current, generating heat for the welding.

Cooling : Phase where the molten metal solidifies after the application of heat.

S

Blowing arc : Deviation of the welding arc by magnetic fields, affecting the quality of the weld.

Welding : Junction obtained by merging together two pieces of metal together.

T

Voltage : Electrical potential difference applied between the electrodes during welding, measured in volts.

Sheet : Thin metal plate which is often used in automotive body and repaired by welding.

W

Welding speed : The speed at which the welding is carried out, which may influence the quality and characteristics of the weld.

Z

heat affected Zone (HAZ) : The area of the base metal, the structure of which is modified by the heat of welding, but that does not fade.

This glossary covers the key terms used in the welding and repair in the auto body. It serves as a reference for understanding the key concepts and processes involved in the use of a spot welder.

A better understanding of the spot welder

Explanation of terms relating to welding by points in the body.

Weld Spotter

Definition : A ‘weld spotter’ is usually a device or a tool used to precisely locate the place where the spot welds must be performed. In the broader context, it can also designate an operator or a machine specialized in the realization of welds by points.

Use in Body : In body, a weld spotter is crucial to ensure that the welds are performed in the exact locations needed to maintain the structural integrity of the vehicle. This is particularly important during the repair of body panels, where precision is essential to prevent further damage and to ensure a high quality finish.

Welding Spot

Definition : The term ‘welding spot’ refers to the specific location where a spot weld is made. A spot welding is a resistance welding technology. Two or more sheets of metal are welded together in a specific point. For this we apply heat and pressure.

Use in Body : In body, the welding spots use to assemble metal parts quickly and efficiently. The welds by points secure body panels between them. This allows you to build structures or to repair damaged areas without having to dismantle large sections of the vehicle. This method allows you to minimize the distortions and get a smooth finish.

Welding Point

Definition : A ‘position of spot welding’ is a station specially designed to perform welds by points. It typically includes electrodes to apply an electric current. The necessary pressure allows to fuse the metals together at a specific point.

Use :Body position of spot welding is an essential tool for repairs and assemblies. It allows the bodybuilder to achieve welds, solid and precise. It acts on the body panels and the frames of the vehicles. The position of point welding typical allows you to control the power, duration, and pressure welding. Cis crucial in order to adapt to the different thicknesses and types of metals used in car bodies.